We craft sustainable benchtops

For us, sustainability is more than a goal. It’s a principle.

Aligned with the essence of our time, nature, and humanity,

we hold a steadfast commitment to our planet’s well-being.

We invest in sustainable and safety-oriented initiatives across our product lifecycle. From manufacturing and fabrication to end use, we take responsibility for promoting practices capable of leading change in our market towards a greener future.

Our environmental, social and governance (ESG) excellence is embedded in everything we do, as demonstrated in our ESG progress report for 2021-2022.

Caring with our raw materials

Sourcing responsibly to maximise sustainable footprint.

Our global suppliers provide quality materials while meeting our environmental and social standards.

Partnerships that do good.

The partners we choose, fully comply with the industry’s supplier code of conduct and are committed to safeguarding the environment and human rights.

Ongoing monitoring and compliance control.

Ongoing testing, checking, and monitoring, constantly improves our practices. We also conduct regular on-site visits to our partners’ facilities to ensure their full compliance with all the regulations regarding human rights and material resources.

Increased volume of recycling.

We are transitioning into recycled paper in our production processes, and in 2021 recycled more than 1,200 tons of paper while also recycling 100,000 raw-material bags every year.

Meeting the mark, with the SCS Green Stamp of approval

Some Caesarstone® models are SCS certified for recycled content, made with up to 40% pre-consumer recycled crushed glass content.

Caring with our manufacturing and transportation

Efficiency that minimises climate change.

Maximising efficiency is a top priority in energy, water, waste, and resource use, implemented throughout our production process while transitioning into renewable energy that minimises our climate footprint.

10% less energy consumption by 2025.

By reducing our energy consumption year-by-year. With a 4% reduction in 2020, we expect to meet our goal of another 10% reduction by 2025.

Slashing GHG emissions.

We are fulfilling our commitment to reducing global GHG emissions, with a 12% reduction in 2018 and 5% reduction in 2019, while monitoring and minimising air pollutants (NOx, Sox, etc.) that impact climate change and health.

Minimising water-use.

Our water use has dropped by 24% per slab since 2015, and we are committed to lowering this number by 10% per slab by 2025.

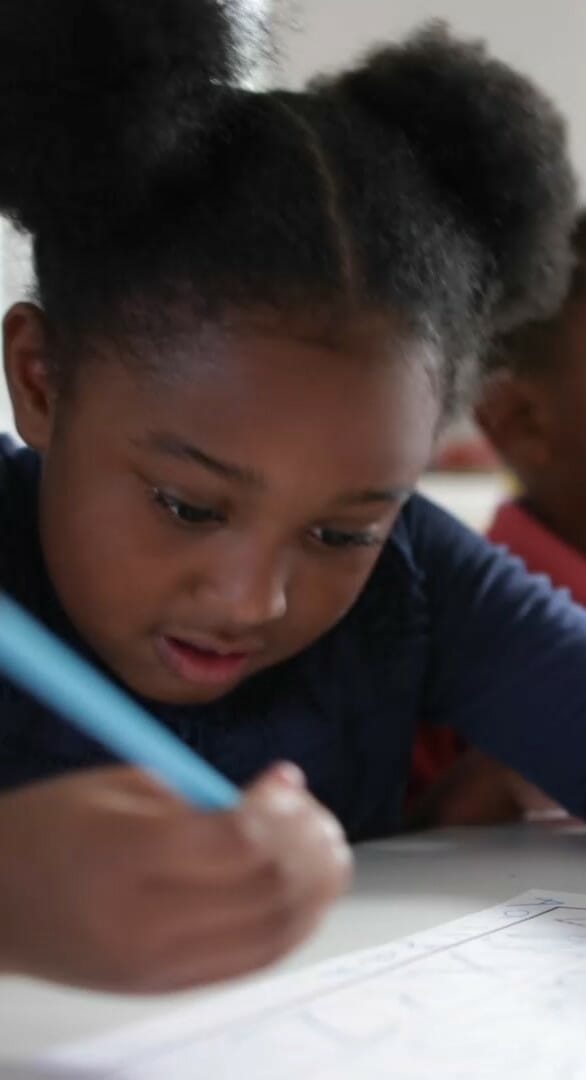

Safety and health first.

A strong safety culture is instilled worldwide through our education and training programs, already achieving 72% less injuries (LTI) from 2018 to 2020 and constantly improving processes.

40 projects dedicated to enhancing safety and health.

We are investing in more than 40 projects, dedicated to reducing the use of hazardous materials (silica, styrene and acetone) in production facilities.

Caring through our use phase, recycling, and disposal.

Global chain of partnerships for positive change.

’Stronger Together’ is a key motto we operate by, and that’s why we initiate and nurture a network of partnerships that drive sustainability across the globe and implement sustainability in the diverse aspects of our product life cycle.

Our products are long-lasting and low-maintenance for a healthier ecosystem.

Our durable, simple-to-care surfaces require no sealants and remain durable and beautiful with minimal maintenance, significantly reducing the use of cleaning detergents.

Lifetime warranty.

We are committed to crafting sustainable surfaces of superior quality that come with our lifetime warranty, reflecting their high performance and durability .

Got the GREENGUARD stamp of approval.

All our products are GREENGUARD certified, as low-emitting surfaces that meet the most stringent product emission standards.

Evaluating opportunities for surface recycling or reuse.

We are establishing safe and efficient ways to reuse and recycle our surfaces at end-of-life, meeting our commitment to minimising waste and maximising efficiency.

Our fabricators’ health and safety are top priority.

We are proactively committed to ensuring a healthy workforce. Our Master of Stone program sets the standard for safety through training and access to knowledge, securing the health of our employees, suppliers, and partners.

Used in green-building projects worldwide.

We are part of GBCA, green building boards and run certified production plants that manufacture green products used abundantly in green construction projects worldwide for their eco-friendly manufacturing and improved lifecycle cost.

NSF Safe

Our nonporous, hygienic surfaces are NSF-compliant and approved by The International Health and Safety Foundation as safe working surfaces for food preparation.

We avoid using Red List materials

We publish a Red List declaration, self-certifying that none of our products include any of the red-listed materials as detailed on the International Living Future Institute website to ensure the health of people and the environment.

Third-party verified Declare Label for full transparency

Our ingredients are clearly listed on Declare Labels that are verified and approved by an external third party. You can trust what is in our products, 100% fit for use in Living Building Challenge (LBC) projects, LEED buildings, and International Future Institute (ILFI) initiatives.

We are but one link in a global chain of eco-certified manufacturers.

We are proud to be part of a broad and globe-spanning chain of sustainability partners who are united around a shared goal of creating positive change in the world, helping each other and supporting us on our sustainability journey.